Safety protection, achievement speed - the application of DuPont PPE in the automobile manufacturing industry

Workers in the automotive manufacturing industry face many hazards on the job, such as sharp edges, smooth surfaces covered in oil, molten metal, punctures, exposure to high temperatures, exposure to hazardous chemicals, and exposure to dust, solvents, and spray paint.

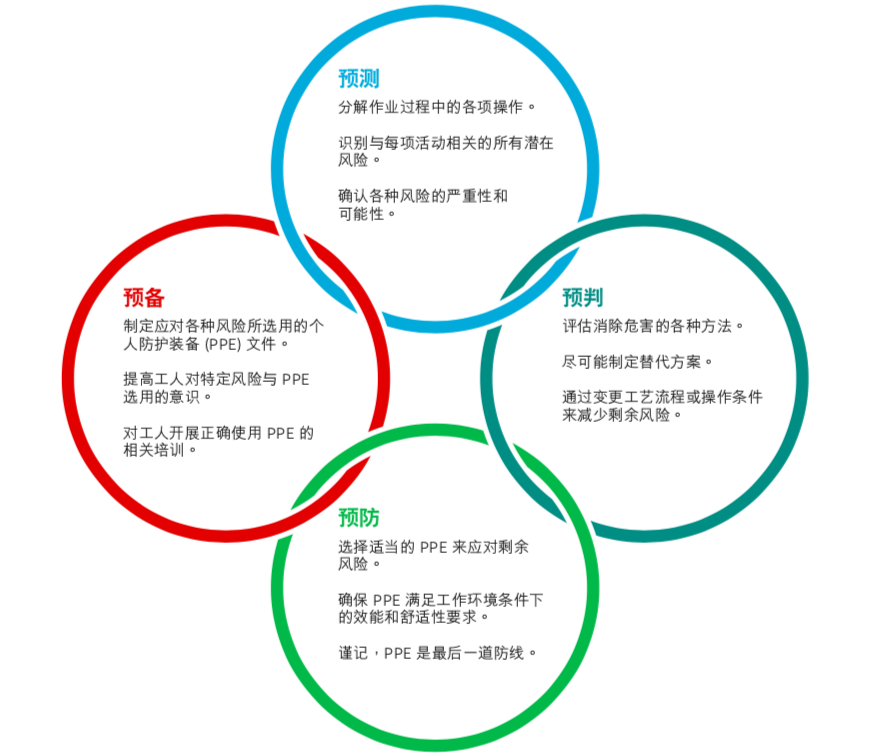

For workers in the auto manufacturing industry, to protect themselves, it is first necessary to anticipate and clarify the risks they face. DuPont has specially designed the Four Preliminary (4P) method, from risk assessment to specific implementation, to help workers make better personal protection decisions

Beyond decision-making, workers in the automotive manufacturing industry in particular need protective gloves and sleeves with the best balance of cut, puncture, heat, grip and dexterity, as well as protection from chemicals and solvents Eroded work clothes. DuPont has a range of personal protective equipment that can be applied to different processes in the industry to provide reliable protection for workers.

Hand protection for workers in auto manufacturing

In the operation process of automobile manufacturing, from stamping, body manufacturing, engine or power battery assembly to final assembly, workers' hands are always ready to deal with various risks such as sharp edges, impacts, oil pollution, molten metal, and high temperature of machinery or components. Only physical , Gloves with reliable chemical protection performance can truly protect their hands.

Kevlar? mechanical protective gloves series have excellent cut resistance, puncture resistance, abrasion resistance, high temperature resistance, Kevlar(r) gloves with high performance rubber coating on the palm can reduce oil and chemical damage, and in dry conditions Provides a good grip, comfortable and breathable, improves the operator's wearing experience and work efficiency, and easily performs punch loading and unloading, parts loading, welding repairs, cylinder head assembly, crankshaft production, wiring harness/interior installation, faults Lots of finesse involved in repairs etc.

Kevlar? yarn glove KK1021B (left) is woven with Kevlar? smooth yarn, cut-resistant up to level 3, low hairiness, moderate thickness, breathable and sweat-absorbing, wear-resistant and durable; Kevlar? yarn glove KK1051 (right) uses Kevlar? yarn Woven, cut resistant up to level 3, with PVC dot beads on the palm surface to improve grip and abrasion resistance.

Chemical Protection for Auto Manufacturing Workers

Dust particles and chemical risks are mainly generated in engine assembly and paint shops, such as cylinder head assembly/production, crankshaft production, as well as grinding, spraying and touch-up operations, which are often exposed to dust, solvents, toxic/corrosive material, etc.

As the world's leading brand of barrier technology, Tyvek? fabric can effectively block dust and particles, with low lint loss, and is very strong, wear-resistant, tear-resistant, stretch-resistant, waterproof, breathable, and comfortable to wear.

Tyvek? 400 TBM 001 protective clothing provides good protection against fine particles and fibers (down to 1 micron in size).

Tyvek? 400 TBM 010 is DuPont's customized protective clothing that is effective against particles such as dust, fiberglass, and aerosols. The fishing line stitching process is adopted to reduce the drop value of protective clothing fibers as much as possible in accordance with the strict requirements of high-end car paint for the painting section; independent workshops are produced separately to avoid complex environmental influences and cross-contamination; the ciliary link is blown and sucked to further reduce ciliary residues.